Copper Alloy Bar

본문

Copper Alloy Bar

Extrude and draw a billet to produce various shapes and sizes of copper alloy bar

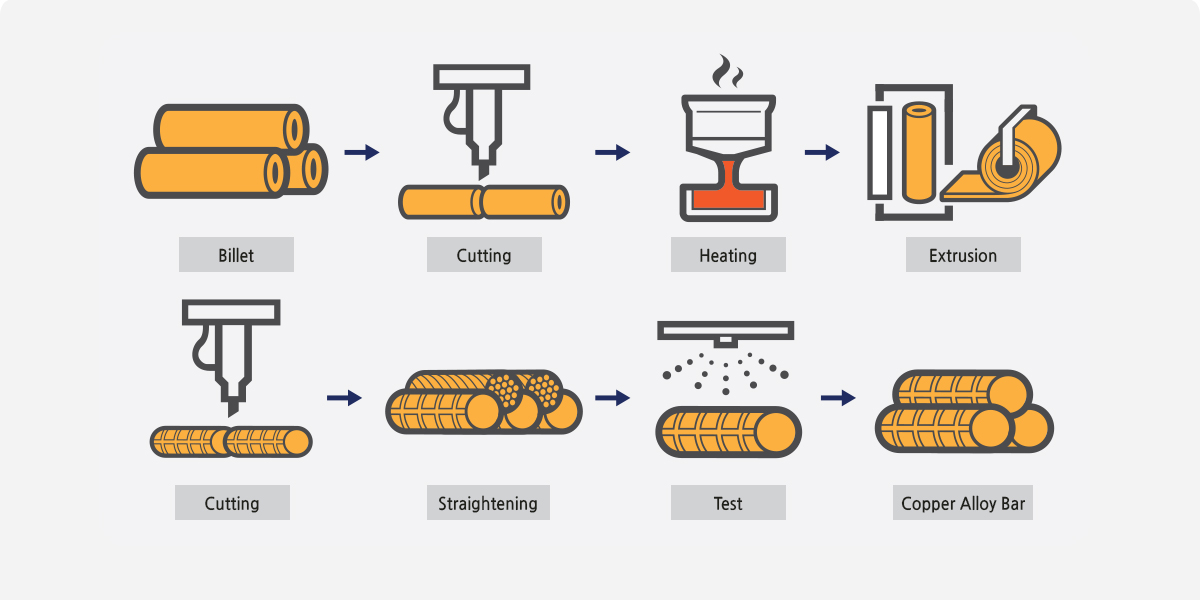

Process of Copper Alloy Bar Production

Available sizes

Check if the dies productin is possible and arrange production

Forged Bar

Forged bar is suitable for precision forging since it bears well in hot forging. Mainly used to produce mechanical components.

| Copper Alloy Bar-Forged Bar : C3771/KSD5101 | ||||||||

|---|---|---|---|---|---|---|---|---|

| CHEMICAL COMPOSITION % | ||||||||

| Composition | Cu | Pb | Fe | Sn | Ni | Al | Mn | Zn |

| Standard | 57-61 | 1.0-2.5 | 0.5↓ | 0.5↓ | - | - | - | REM |

Free Cutting Bar

It is used mainly in spindle, valve or bolt processing because it is suited for cutting.

| copper Alloy Bar-Free Cutting Bar : C3604/KSD5101 | ||||||||

|---|---|---|---|---|---|---|---|---|

| CHEMICAL COMPOSITION % | ||||||||

| Composition | Cu | Pb | Fe | Sn | Ni | Al | Mn | Zn |

| Standard | 57-61 | 1.8-3.7 | 0.5↓ | 0.7↓ | - | - | - | REM |

Naval Bar

It is mainly used in ship component or shaft because it is highly wear/seawater resistant.

| Copper Alloy Bar-Naval Bar : C4622/KSD5101 | ||||||||

|---|---|---|---|---|---|---|---|---|

| CHEMICAL COMPOSITION % | ||||||||

| Composition | Cu | Pb | Fe | Sn | Ni | Al | Mn | Zn |

| Standard | 61.0~64.0 | 0.3↓ | 0.2↓ | 0.7~1.5 | - | - | - | REM |

Product image